Consistently aseptic

Aseptic sampling valves from Guth are ideal for sampling in laboratories and production in the food or beverage industry. They are easy to handle and prevent contamination through their consistently aseptic construction. The samples can be drawn both manually and pneumatically. Our optimised sample drawing operating concept simplifies manual sampling and impresses with its low actuation force.

Compact and easy to use

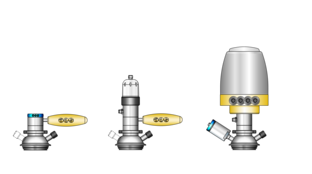

Compact design, safe cleaning and individual equipment characterize the aseptic sampling valves from Guth. The modular system makes it possible to equip or retrofit any valve according to your individual requirements: Always the right solution thanks to over 10,000 possible configurations.

From ergonomic, smooth-running handle to pneumatic actuators with end position feedback to the control head, our aseptic stainless steel valves impress with their ease of use. The flushing connections of the sampling valves allow safe and easy cleaning. Product pressures up to 10 bar (g) are reliably maintained by the newly optimized bellows.

Optional upgrade and retrofitting:

- All actuation variants can be retrofitted

- Electronic control elements

- Control heads

The following drive concepts are available:

- Manual operation (spring closing)

- Manual operation (self-locking)

- Pneumatic actuation

- Pneumatic/manual actuation

![[Translate to Englisch:] Logo Guth Ventiltechnik](/fileadmin/user_upload/01_basic/Logo-Guth.png)